Membrane Nitrogen Generator Hollow Fiber Nitrogen Membrane On-site Nitrogen

- Model

- SMN0100~SMN2000

Item specifics

- Brand

- Scala

- Nitrogen Purity

- 95%~99.5%

- Flow Rate

- 1~2000L/hr

- Voltage

- AC 220V/1PH/50Hz

- Power

- 200W

- Ambient Temperature

- 0~50℃

Review

Description

Working Principle

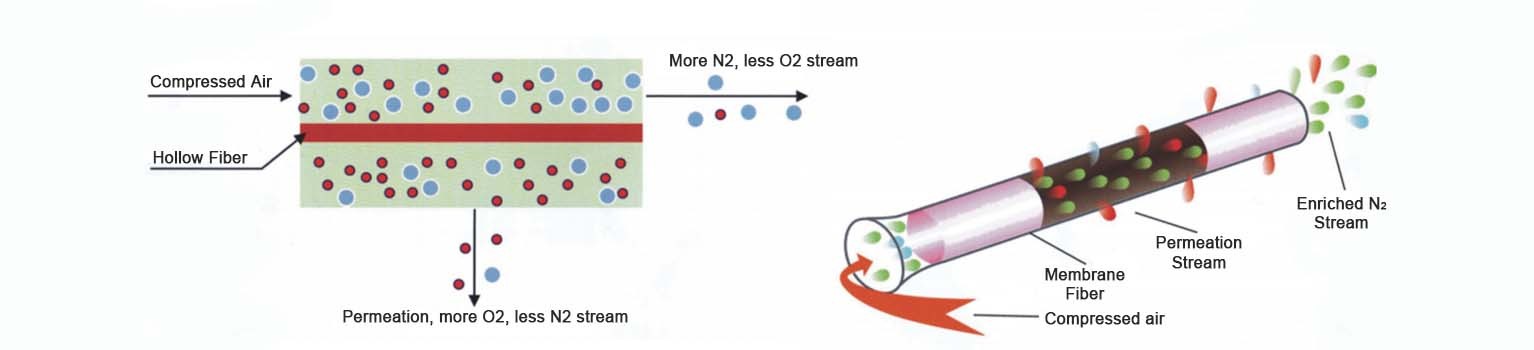

Air separation membrane works like a super-fine filter. Air is pushed through a hollow fiber membrane. Some gases, like oxygen and water vapor, pass through the walls of the membrane. Others gases, like nitrogen, can't pass through and stay inside the fiber.

This separates the air into two streams:

1 stream of oxygen-rich gas that passes through the membrane wall.

1 stream of nitrogen-rich gas that comes out from the other end of the fiber.

A membrane nitrogen generator makes this separation happen with a membrane that consists of thousands of hollow polymer fibers. These fibers have a unique structure that allows only the oxygen and any remaining water vapors in the air to escape through its walls. This process is called "permeation". Once outside the fibers, the O₂ is vented out of the membrane housing and disposed of outside or in a safe area. This leaves the N₂ inside the hollow fibers, ready to be collected at the outlet. With the water vapors removed, the produced nitrogen is very dry, which is an additional benefit for its professional applications.

The reason for the separation of nitrogen and oxygen is the pressure difference inside the hollow fibers and the outside. No need for driving valves or moving parts, simplicity and reliability form the foundation of this technology - from system installation to nitrogen production and associated maintenance. Only constant ambient-temperature clean compressed air (or even humidified) is required. Many nitrogen applications demand high purity for inerting or precise purposes (such as in the food or pharmaceutical industries), and membrane nitrogen generator can produce nitrogen with a purity of up to 99.9%.

Specifications

· Model no.: SMN0001 ~ SMN2000

· Gas Type: Nitrogen (N2)

· Flow Rate: 1~2000 liters/hour

· Purity: 95% - 99.5%

· Oper. Temperature: +0℃~+40℃

· Voltage: 220V/1PH/50Hz

· Power: 0.2kW

· Noise: ≤65dB(a)

Benefits

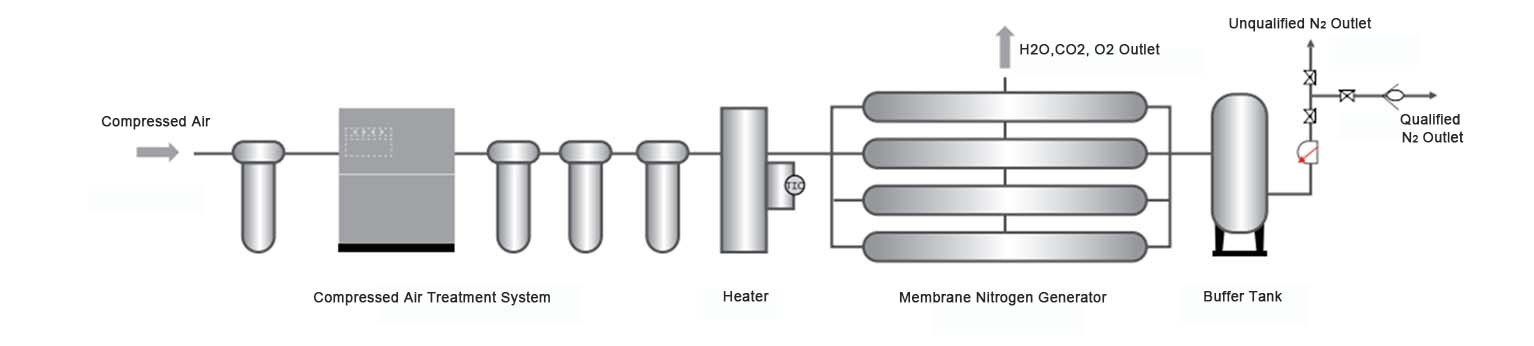

The processes of membrane nitrogen generators and PSA (Pressure Swing Adsorption) nitrogen generators are similar: air is compressed, purified, separated to extract nitrogen, and finally stored in a nitrogen buffer tank. The key difference lies in the method of nitrogen separation. Compared to PSA nitrogen generators, nitrogen purity from membrane nitrogen generator is typically below 99.9%. However, membrane nitrogen generators have their own advantages:

1. Simple operation, high reliability, and a high degree of automation. With no moving parts and no need for cyclic switching, it meets the requirements for long-term continuous operation.

2. Quick and easy start/stop—qualified nitrogen can be produced within about 10 minutes of startup. Low energy consumption during operation, with continuously adjustable nitrogen purity.

3. The gas separation process is noise-free, pollution-free, and produces no harmful waste, ensuring high cleanliness of the generated nitrogen.

4. The nitrogen production capacity can be expanded by adding membrane modules to meet customers' needs for different nitrogen output levels.

5. Equipped with an intake quality detection and protection device for the membrane modules, ensuring only qualified gas enters the membranes and extending their service life.

6. Compact structure, easy installation, small footprint, wide applicability, and resistance to many chemical contaminants.