SVBS-200 Liquid Nitrogen Doser Multi-purpose Liquid Nitrogen (LN2) Dosing System

- Model

- SVBS-200

Item specifics

- Brand

- Scala

- Product Series

- SVBS

- Medium

- Liquid Nitrogen

- Liquid Nitrogen Pressure

- 3 - 22 psi

- Gaseous Nitrogen

- 60 - 100 psi

- Head Pressure

- 0.45 psi (0.03 bar)

- Electricity

- 110-240VAC; 50/60Hz

- Power

- 110W

Review

Description

Description

The SVBS-200 is a multi-purpose liquid nitrogen (LN2) dosing system utilizing advanced cryogenic technology and PLC programming.

Scala engineers designed this ultra-efficient system for low to medium production line speeds to dispense a precise dose of liquid nitrogen into every container every time. The liquid nitrogen gasifies and is either trapped in the container to add rigidity or escapes with oxygen to inert the headspace.

How It Works

Liquid nitrogen is supplied to the SVBS-200 by a standard 10ft (3mt) vacuum insulated liquid nitrogen hose (various lengths available) and flows into the dosing head. A 24vdc PNP sensor detects the speed of the line (encoder compatible for higher speeds); a second 24vdc PNP sensor detects the presence of a container. When a container is detected, the dosing head opens and dispenses an exact amount of pure liquid nitrogen.

Features

· Compact Size – enables installation in limited spaces.

· Precise Dosing – delivers consistent, accurate dosing.

· Discrete Dosing – up to 500 containers per minute (controller dependant).

· Discreteor Continuous Dosing – change over defined by user.

· Vacuum Insulated Technology – the most efficient use of LN2.

· Soft Dose Compatible – Scala's proven technology for hotfill, powder, and granular applications.

Benefits

• Lightweight PET – reduce the weight of PET for cost and environmental savings

• Glass to PET Transition – eliminate glass safety hazards and weight of containers

• Bottle Rigidity – maintain bottle shape even with lighter bottle wall

• Eliminate Paneling – increase the internal pressure to offset paneling issues

• Oxygen Reduction – create an inert environment to preserve product freshness

• Extend Shelf Life – minimize oxygen levels

• Ease of Labeling – consistent bottle rigidity creates labeling convenience

• Reduce Nitrogen Consumption – measurable and repeatable liquid doses

• Maximize Warehouse Storage Space – increasing product stackability utilizes less square footage

• Stabilize Organic Products – extend shelf life without preservatives

Specifications

| Model | SVBS-200 |

| Weight | 15kg |

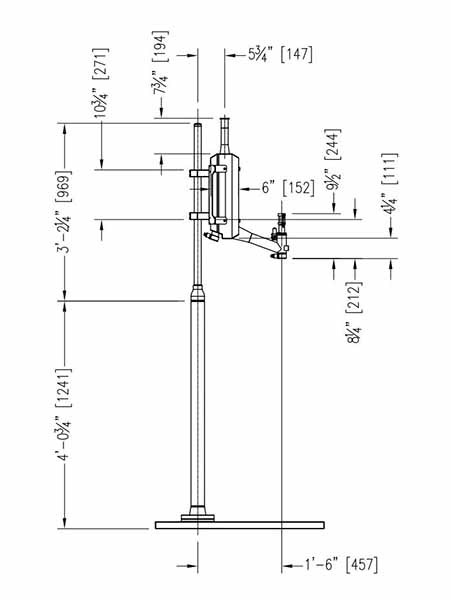

| Dimension | 700x159mm |

| Dosing Head Dimension | 270x57mm |

| Arm Reach | 380mm |

Nozzles | 0.02'' ~ 0.12'' Available |

Liquid Nitrogen | 3 ~ 22 psi |

Gaseous Nitrogen | 60 ~ 100 psi |

Electricity | 110~240VAC; 50/60Hz |

Power | 110W |

Steady State Consumption | 0.04 gal (0.2 liter) / hour |

Quick Service | No |

Vacuum Insulated | Yes |

Flexible Arm | No |

SoftDose Compatible | Yes |

Controller

| Dimension | 19.8"H x 7.8"D x 12.3"W (503 x 198 x 312 mm) | |

| Weight | 22.5 lbs (10.2 kg) | |

| PLC Platform | Siemens | |

| Dosing Range | 0.5 - 12g/second | |

Time Range | 15 to 500 ms (in 1ms intervals) | |

Encoder Compatible | Yes | |

Discrate Dosing | Up to 1200 cpm | |

Line Speed Auto Detect | Yes | |

Speed Compensated Mode | Yes | |

Electronic Dose Targeting | Yes | |

Fixed Delay Mode | Yes | |

Accuracy | ± 2% of dose value | |

Multiple Language | No | |

Recipe Storage | Yes | |

Projects

SVBS-200

Soybean Source

SVBS-200

Beer Package