Avoid These 8 Liquid Nitrogen Generator Pitfalls: Advice from Professional Manufacturers

- Share

- publisher

- Jude

- Issue Time

- Sep 10,2025

Summary

On site liquid nitrogen generators are unfamiliar to many lab users, making it difficult to judge their professional performance and suitability.

Abstract

Liquid nitrogen generators are unfamiliar to many lab users, making it difficult to judge their professional performance and suitability. This can lead to purchasing equipment that looks attractive but hides shoddy workmanship and quality hazards. Focusing on the common 10L/day specification, professional manufacturers have summarized 8 key pitfalls to avoid, helping users make accurate and informed selections.

1. Cryo-cooler: Warranty Commitment is the "Bottom Line"

Production Process Difficulty

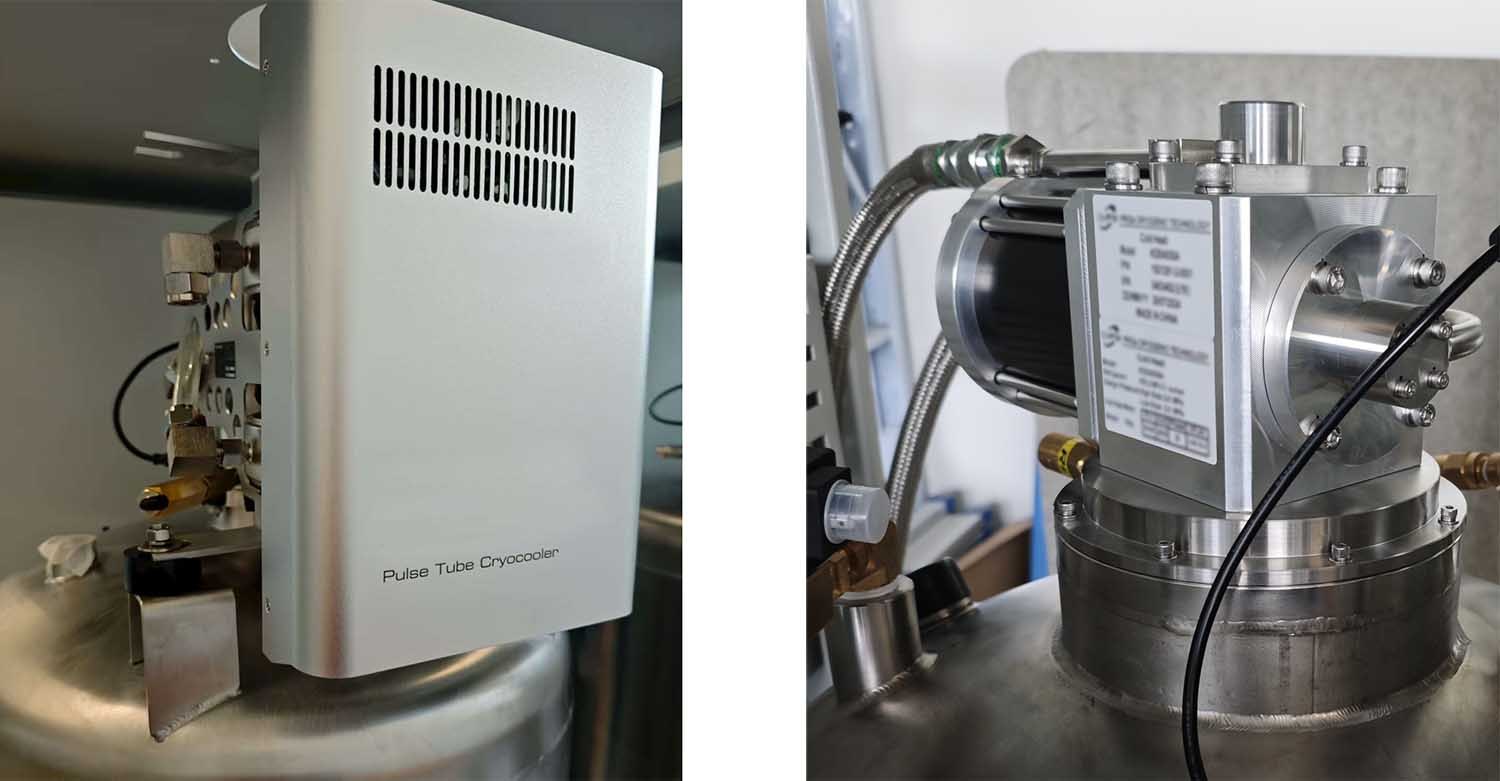

Small scale liquid nitrogen generators primarily rely on two types of cryocooler technologies to achieve the necessary ultra-low liquefaction temperature: the hybrid Pulse Tube cryocooler and the Gifford-McMahon (GM) cold head. These are cryocoolers that have been put into batches commercial production and internationally certified such as CE and UL. Immature or newly developed production technologies often lack a verified history of long-term, reliable operation. This makes it exceptionally difficult for non-professional users to accurately assess their quality and durability.

Key Point to Avoid Pitfalls

Forget specific production processes or technology. The key to mitigating risk is to demand real-world usage cases demonstrating reliable operation, along with valid international safety certifications like CE for the cryocooler. Furthermore, the manufacturer must back this claim with a comprehensive 3~5 years warranty or free replacement policy for the cryocooler.

2. Reject "Low-Temperature Restriction": Prioritize Equipment Operable at Normal Temperature (30℃/86℉)

The Trap

To cut costs, some manufacturers replace proper water chillers with air-cooled condensers that has no refrigeration capacity and label the operating temperature at a restrictive "0-25°C". Since most conventional laboratories consistently operate above 25°C, this design is fundamentally unacceptable. The critical pitfall is that the unit will automatically shut down when the ambient temperature exceeds its narrow range, leading to failed experiments and significant operational downtime.

Key Point to Confirm before Purchase

To ensure reliable operation and avoid interruptions due to overheating, always confirm that the generator is rated for stable, continuous operation in a conventional laboratory environment of 30°C (86°F) or higher.

3. Beware of Inflated Output Claims

Core Issue

Some manufacturers advertise a generous output like 10L/day to justify a low price competition. However, independent verification often reveals actual production is significantly lower (e.g., only 6L/day), rendering the equipment inadequate for its intended use.

Tip to Avoid Pitfall

Request the manufacturers to present actual output test report with detailed data.

4. Built-in Liquid Nitrogen Dewar: Small Volume + Quick Evaporation = "Useless"

Volume Trap

A small-scale generator needs to operate for 2-3 days to store enough liquid nitrogen. To compromise for an impractically small size, some manufacturers squeeze 20 liters volume or even smaller in-build dewar into the cabinet. This creates a critical limitation: when liquefaction stops, the liquid level immediately begins to drop due to evaporation. Factoring in the necessary headspace (10-20% nominal capacity) and continuous evaporation, the actual usable liquid nitrogen volume is about 10 liters, making the system inefficient for sustained use.

Evaporation Rate Risk

Poor-quality + anti-thermology-design tanks will cause liquid nitrogen vaporize completely in 2-3 days, even worse scenario is fast vacuum loss in 3 years, leading to a sharp drop of liquid nitrogen production.

Mandatory Requirement

Choose a liquid nitrogen generator with 35L or larger in-built dewar and request 5-year warranty for the dewar.

5. Self-Maintainability: Avoid "Exorbitant On-Site Maintenance Fees"

Manifestation of the Trap

Some generators are not designed to be maintenance-friendly and rely on on-site services from the manufacturer/distributor, resulting in high subsequent maintenance costs.

Purchasing Tip

Prioritize liquid nitrogen generator with modular components. You can intuitively judge whether it is convenient for users to perform self-maintenance and replace accessories, thereby reducing long-term maintenance costs.

6. Air Compressor: Stick to Maintenance Cycle of "10,000 Hours +"

Problem with Poor-Quality Compressor

Low-priced air compressors typically offer significantly short service life and require part replacements every 4,000 hours, leading to higher long-term consumable costs and bad user experience.

Qualified Standard

A high quality air compressor's maintenance cycle often exceeds more than every 10,000 hours, or even up to 15,000 hours. Always remember to verify the manufacturer's commitment to the service life of the air compressor if you want to have a reliable liquid nitrogen generator.

7. Nitrogen Generator: Verify Manufacturing Technology and Service Life

Manufacturing Technology Selection

Prioritize pressure swing adsorption (PSA) technology nitrogen generators, which will produce 99.5% and higher purity nitrogen gas while membrane nitrogen generation technology can achieve upmost 98% purity, so you need to carefully evaluate which type meets your needs. Some manufacturers claim over 99.9% nitrogen purity, but actual purity may only be 98%. It is recommended to ask the manufacturer to provide a purity commitment document.

Service Life Requirement

Due to the short service life (as little as 3 years) of poor-quality components, require the manufacturer to guarantee a lifespan of over 8 years for the nitrogen generator, especially the unit with nitrogen membrane module technology.

8. Beware of "False Labeling" or "Exceeding Standard" Noise Parameters

Reasonable Range

A reasonable operating noise level for laboratory equipment is typically below 63 decibels (dB), with conventional nitrogen generators operating at approximately 60 dB. Therefore, a manufacturer's claim within the range of 60-63 dB is credible, while claims significantly lower than this should be scrutinized.

Key Point to Avoid Pitfall

A specification of 68 dB is inappropriate for most labs but suggests a industrial-grade unit. A claim of 55 dB is a significant red flag for false labeling. You must formally request and review the official noise test report from the manufacturer before purchase.

Professional Manufacturer's Advisory

When purchasing a liquid nitrogen generator, avoid the "low-price trap." Instead, prioritize core performance (measured by output and stability) and evaluate long-term operational costs (including warranty terms and maintenance expenses). The most reliable strategy is to insist on clear, documented commitments for all performance parameters. This due diligence is the only way to select equipment that is truly worth the investment and guaranteed to operate stably.