16 Reasons Scala's LNS10A Beats Traditional Liquid Nitrogen Generators (2/3)

- Share

- publisher

- Jude Cao

- Issue Time

- May 28,2025

Summary

Competitors’ liquid nitrogen generators drain budgets and harm the planet. Here's how Scala's LNS10A delivers 99.999% purity while slashing your carbon footprint.

Smart Technology & Automation: 6 Ways Scala's LNS10A Outshines Other Brands

Competitors' machine drain budgets and harm the planet. Here's how Scala's LNS10A liquid nitrogen generator delivers 99.999% purity while slashing your carbon footprint.

Abstract

Competitors' liquid nitrogen generators waste resources, lack purity, and harm productivity. This article breaks down how Scala's LNS10A combines a pulse-tube cryocooler, zero exhaust, and ultra-high purity to slash costs, boost sustainability, and meet the demands of critical industries.

Introduction

The hidden costs of traditional liquid nitrogen systems go beyond dollars - think energy waste, environmental impact, and compromised purity (seldom product can hardly reach). Scala's LNS10A liquid nitrogen generator redefines efficiency with 99.999% purity, zero gas exhaust, and innovative engineering designed for industries that refuse to compromise.

1. Pulse-Tube Cryo Cooler (No Ice Buildup)

Competitors' generators often fail due to ice-clogged components. The LNS10A's pulse-tube cryo cooler eliminates ice formation entirely, ensuring uninterrupted 24/7 operation—a lifesaver for IVF clinics and food processing plants.

Learn more about Pulse-Tube Cryo Cooler: https://www.scalacryo.com/comm07/Pulse-Tube-Croycooler.htm

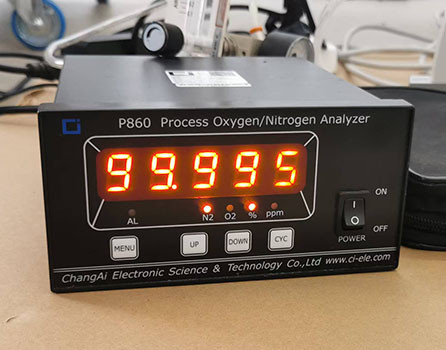

2. Ultra-High 99.999% Nitrogen Purity

While mix-refrigerant cryocooler max out at 95~99% purity, the LNS10A delivers 99.999% nitrogen, meeting stringent standards for semiconductor fabrication and medical-grade applications.

LNS10A integrated Scala self-developed PSA nitrogen generation system with high performance molecular sieves into the machine, combined with high precision filtration & drying module, make the liquid nitrogen purity easily reach to 99.995%.

3. 35 Liters Volume Built-In Dewar

Why do we need large volume dewar in liquid nitrogen generators?

1) Unlike common fluid like water or oil we see in everyday life, liquid nitrogen boiling temperature is -196℃, which means it evaporates fast at ambient temperature and also means a lot liquid nitrogen waste at transferring or in applications. Larger dewar means you can always have enough liquid nitrogen.

2) Larger dewar also ensures you can turn off your liquid nitrogen from time to time for maintenance so your machine can serve for longer time.

3) In LNS10A we pre in-build 35 liters dewar, compared to other brands which come with 15 or 20 liter dewar, LNS10A can better satisfy your everyday needs for liquid nitrogen.

4. All-in-One Design (No External Air Compressor)

We see many other brands on market displaying their so-called liquid nitrogen generators, which from our eyes are actually nitrogen gas liquefiers.

Liquid nitrogen generating is no easy job. You need at least 4 main parts to make self-sufficient liquid nitrogen: an air compressor + a nitrogen generator to make nitrogen gas, a vacuum insulated dewar + cryocooler to get nitrogen gas liquefied. And apart from the main parts it also needs a controlling system and water chiller if necessary. Some brands only supply cryocooler and state it as liquid nitrogen generator, you have to buy other equipment to fit this liquefier to make liquid nitrogen.

In LNS10A we integrated oil-free air compressor, PSA nitrogen generator, high vacuum dewar, high performance pulse tube cryocooler, water chiller and industrial grade controlling system into a compact unit, making it a reliable, cost effective and super quiet machine for your lab or applications.

5. Zero Nitrogen Exhaust

Competitors waste up to 50% of nitrogen gas because nitrogen was liquefied inside a liquefier. LNS10A's closed-loop system ensures 100% nitrogen gas utilization as it was liquefied directly in dewar, reducing energy cost and environmental impact.

6. 57 dB(A) Quiet Operation

At noise levels quieter than a conversation (57 dB(A)), the LNS10A fits seamlessly into labs and hospitals. Competitors’ 60–70 dB(A) machines disrupt workflows and require soundproofing.

We made everything to lower noise of LNS10A:

1)The cabinet board is totally walled with high performance acoustic foam.

2)Extra large muffler for pressure release from dewar.

3)Double silencers to reduce noise of compressor and nitrogen filtration.

Cut waste and boost purity—request a quote. Next, learn how Scala’s LNS10A simplifies maintenance